Major Technology

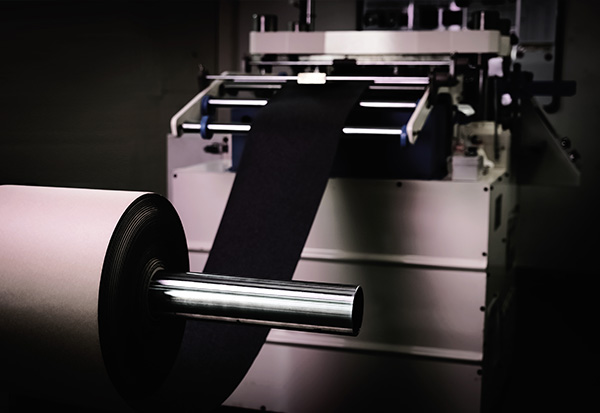

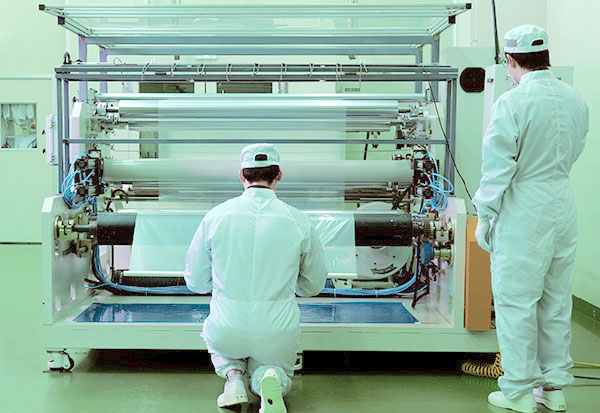

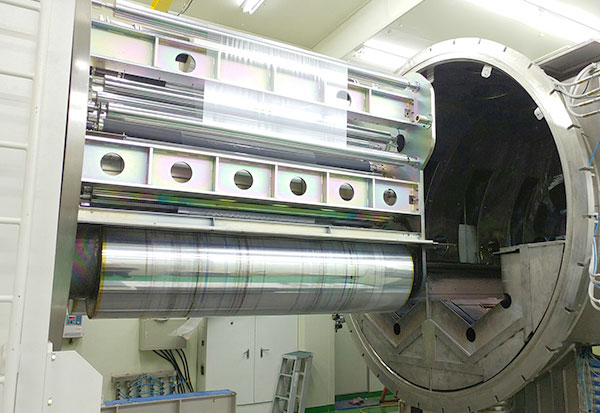

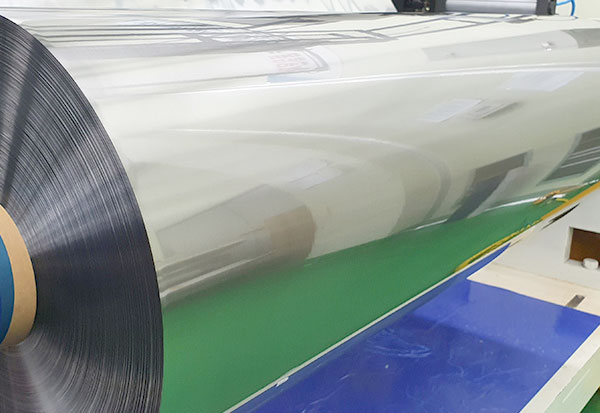

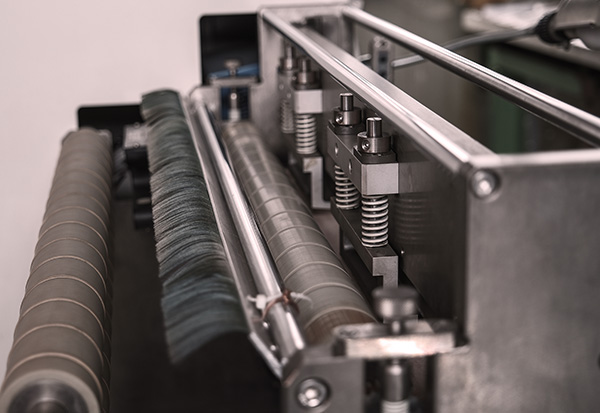

Film Deposition Division: Sputtering multilayer thin-film continuous deposition technology based on roll-to-roll method

Roll-to-roll film control technology

Capable of continuous deposition of six types of metal

Can deposit wide width (1,400mm) materials on a wide area

Sputtering

Plasma is formed in vacuum by injecting small amount of Ar gas to generate sputtering.

When voltage is applied using the metal target as the cathode, electrons collide with Ar atoms to ionize them into Ar+. When ionized Ar+ atoms continue to collide with the cathode target, target atoms are emitted as molecules and atoms to attach to the substrate.

Operation of Sputter Device

- Vacuum exhaust: There are oil diffuser pumps that have a high exhaust rate and low price, but they accompany back-diffusion of molecules. Therefore, it is necessary to use a dry pump, turbo molecule pump, or cryogenic pump that does not use oil. The dry pump can suck at initial low vacuum, and the cryogenic pump is used to exhaust air at lower vacuum.

- Effects of moisture: Moisture affects the coloring process. When the chamber is opened, moisture is absorbed. High temperature and pressure are used to reduce moisture adhesion. Moisture adhesion is higher at low temperatures, and pressure is lowered in comparison to the high-temperature process. When returning to atmospheric pressure or opening the door, nitrogen gas must be used to prevent the air containing moisture from entering.

-

Process pressure: Coloring of light interference comprises the lowermost reflection layer (metal layer of Al or Cr in general) and the dielectric layer on top, which is a multi-interference layer. Gas (Ar) pressure needs to be maintained constant inside the chamber to form a film in a reproducible way, and the following methods are available.

- Method of reducing the gas volume: Since nitrogen and oxygen are used up as nitride and oxide layers, the volume of Ar gas is increased. Only Ar gas is used in the metal mode, and Ar is not used up. It is important to regulate pressure inside the chamber.

- Method of increasing the gas volume: This responsive mode forms the dielectric layer as an interference layer. Reactive nitrogen and oxygen gases are turned into nitride and oxide layers. The injection volume should be greater than the amount used as nitrides and oxides.

Specialty Sputtered Coatings (Metals/Oxldes)

|

|

|

|

Typical Applications

|

|

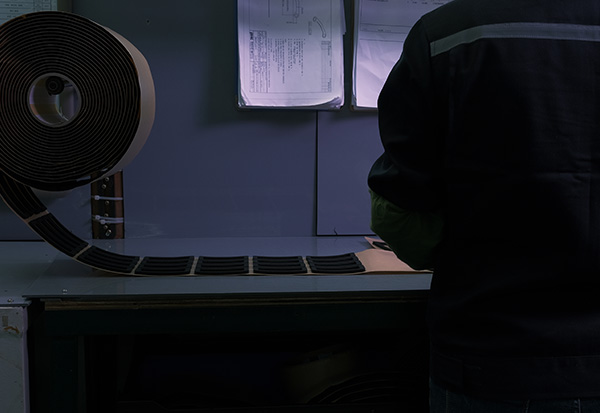

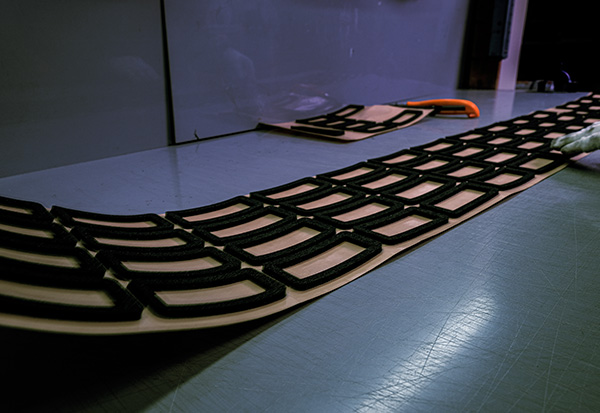

Foamed Pad Division: Process management through precise control of pads and multi-variety materials

Multi-variety wooden pattern manufacturing technology

Processing technology with precise control of pad materials

Optimized inventory management for multi-variety materials