Product Introduction

Product Introduction : Vinyl Coated Metal (VCM) Pattern Film

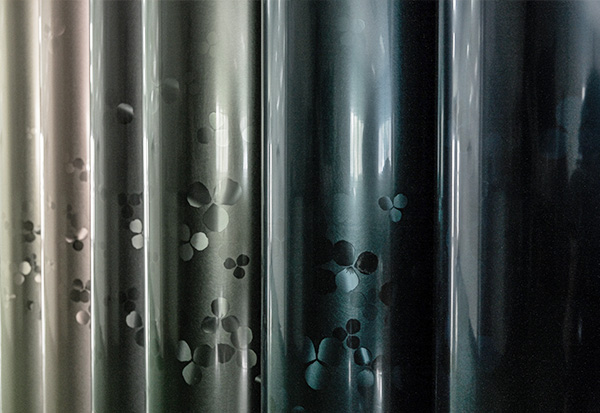

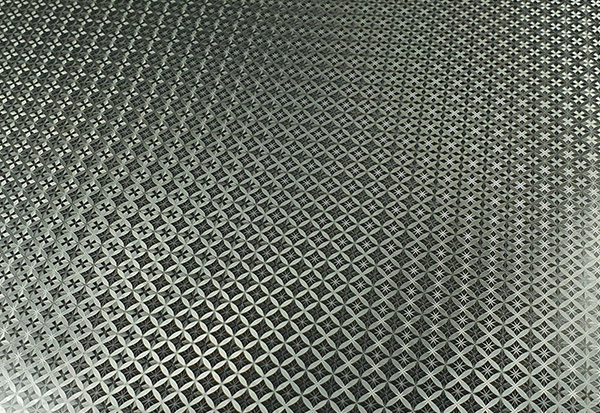

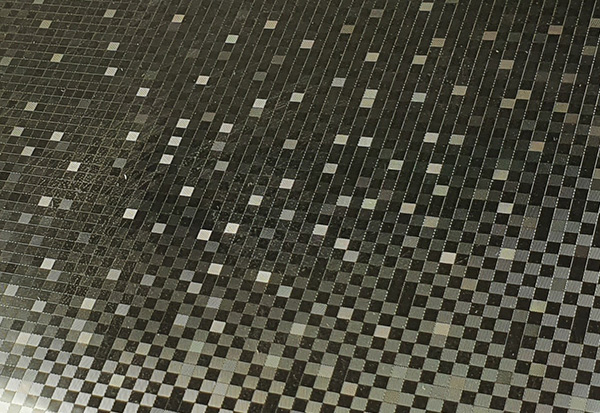

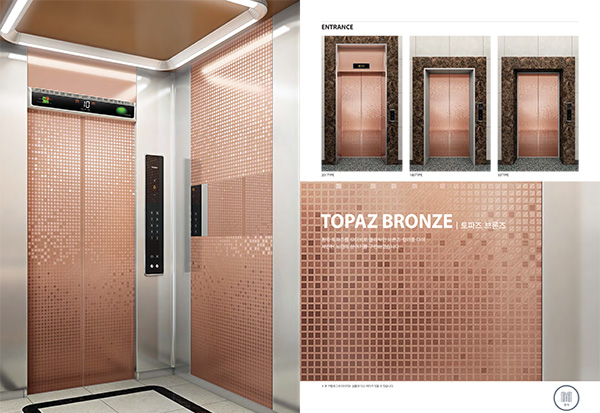

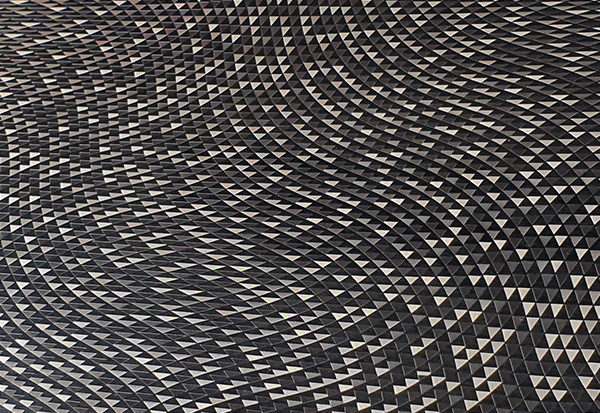

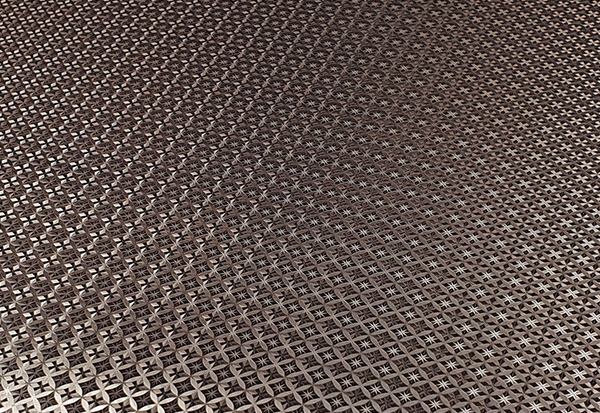

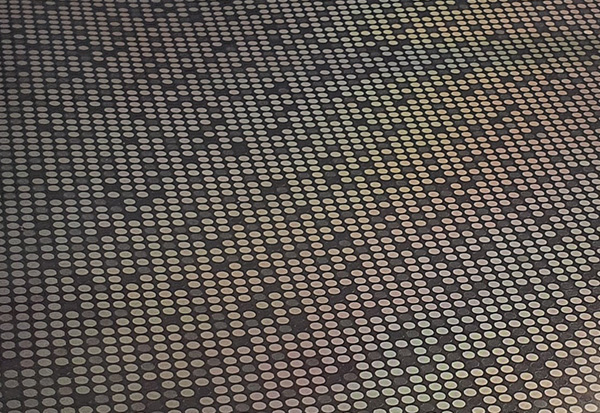

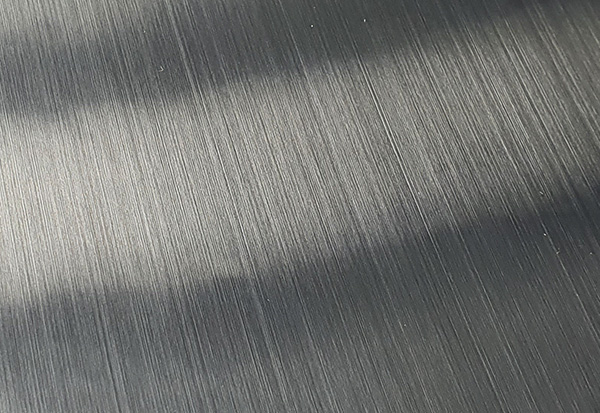

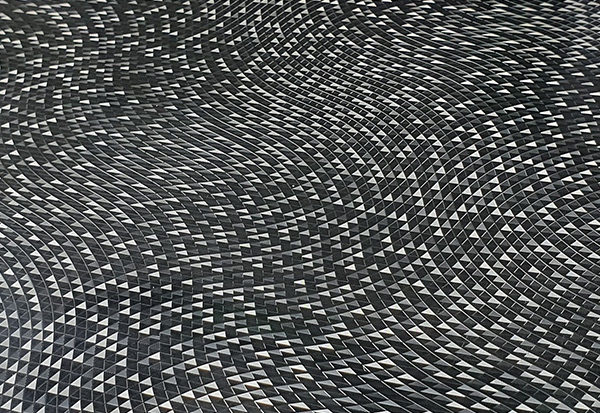

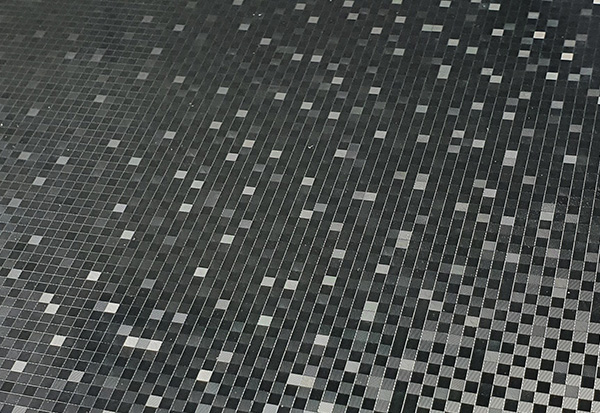

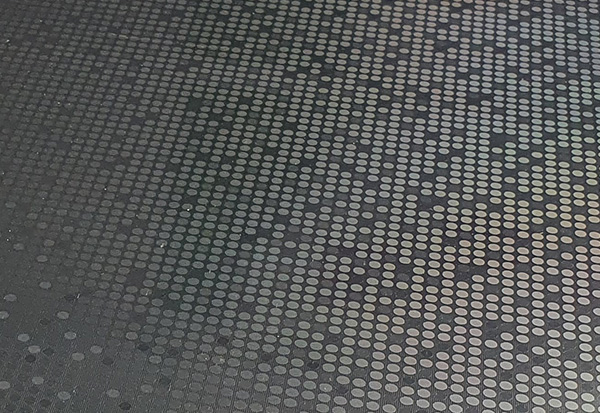

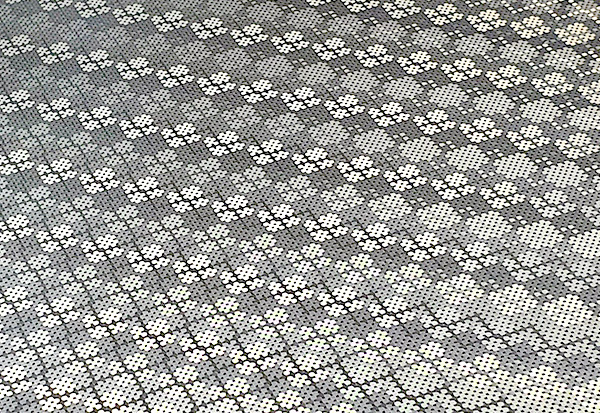

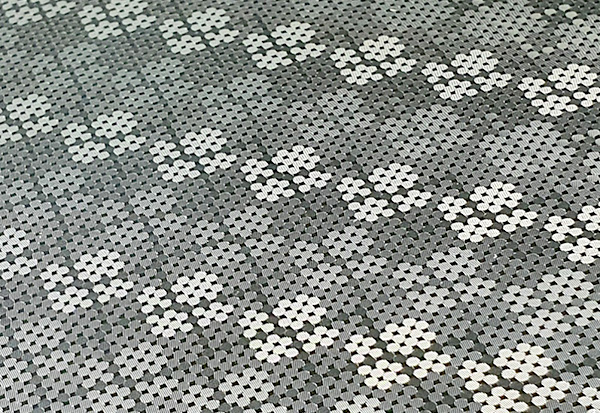

VCM pattern films are products used to add a luxurious appearance to architecture, home appliance, and furniture by laminating films on various materials like plastics, glass, steel sheets, and wood with an adhesive. These decoration films have the beautiful look of metallic texture by forming an optical pattern structure based on the physically scraping brush method and imprinting method. They are attached to non-metallic materials to create a metallic surface with different colors, patterns, textures, and gloss.

Product Characteristics : Premium product that uses different patterns and a luxurious metallic color

PET/PVC films made by sputtering deposition have better corrosion resistance and adhesiveness compared to thin films based on the ordinary thermal deposition method. When making these thin films, various colors can be embodied through responsive deposition by injecting gases (oxygen, nitrogen). If applied to products, these films can produce luxurious appearance with the feel of stainless steel.

* Special durability through continuous coating of oxidation protection layer using a technology that can deposit six types of metal simultaneously

* Capable of creating patterns (brush type (physical scraping), imprinting embossing type)

Applied Fields

Elevator interior materials for architecture, refrigerator doors and washing machines for home use, interior furniture, and so on

Embodiment of colors through the design of alloy ratio and oxidation prevention layer

Sputtering Deposition [Gold] ※ Derived deposition colors : Champagne Gold, Titan Gold, etc.

Sputtering Deposition [Bronze] ※ Derived deposition colors : Rose Gold, Dark Pink, etc.

Sputtering Deposition [Black] ※ Derived deposition colors : Black Diamond, Deep Black, etc.

Sputtering Deposition [Metal Silver] ※ Derived deposition colors : Light Silver, Real Steel, etc.

Embodiment of colors through responsive sputtering deposition (thin film design using oxides and nitrides)

Coloring through multilayer thin films can create diverse colors by controlling the refractive index according to thickness of each metallic substance, considering the reflection rate of diffused light reflection, brightness, transmittance, and absorption rate.

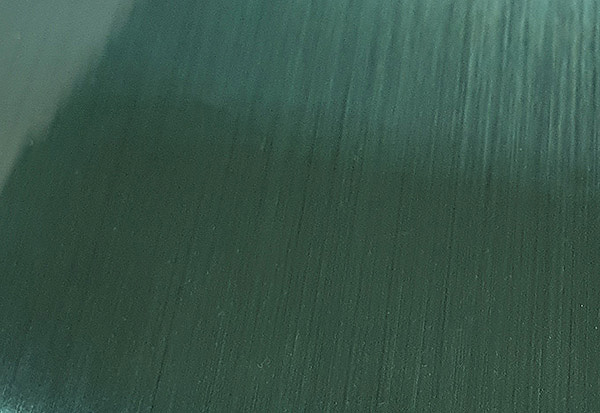

Sputtering Deposition

[Metallic Green]

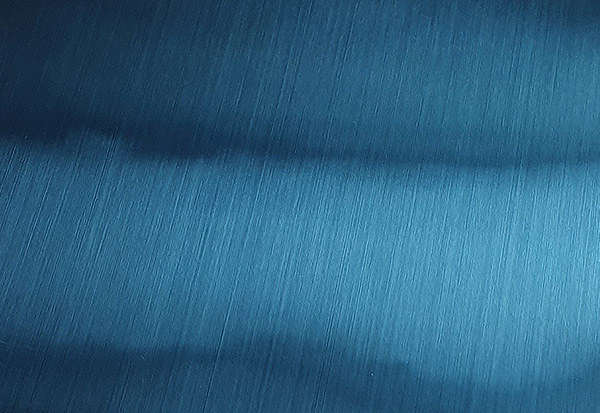

Sputtering Deposition

[Deep Sky Blue]

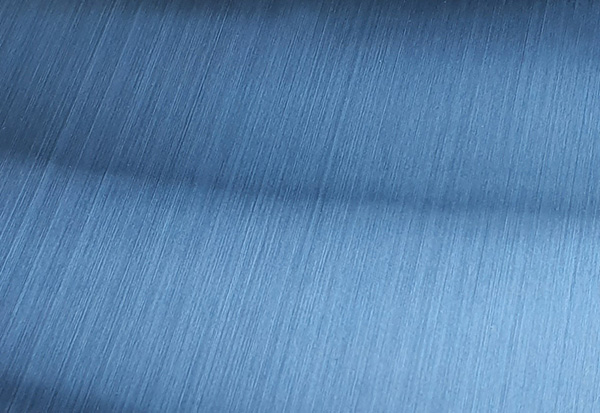

Sputtering Deposition

[Dark Blue]

Sputtering Deposition

[Purple]

Sputtering Deposition

[Red Wine]

Sputtering Deposition

[Brown]

Coloring by sputter has a metallic feel and can make products appear luxurious with an outstanding reflection rate compared to colors created by printing technologies. Scattering by diffused reflection is reduced to increase the coloring effect. The thin-film structure can be designed with low transmittance and absorption rate to raise the reflection rate.

In the coloring method using the interference of light, monolayers can make different colors by changing thickness through anodic oxidation of Ti and TiO2 layers, placing the TiO2 layer on top of the Ti layer. Multilayers thinly alternate between TiO2 and SiO2 layers that have different refractive indexes for lamination and interference. For bright colors, an aluminum reflection film with a high reflection rate is used. Chromium is used to lower the reflection rate.