Equipment Status

Produced Equipment

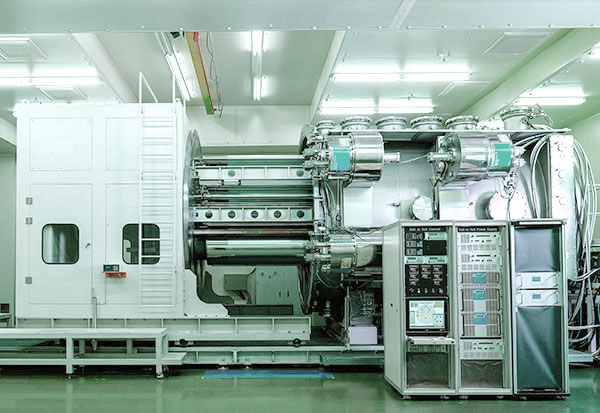

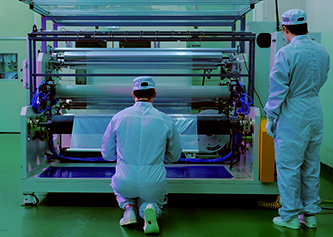

Roll-to-Roll Continuous Vacuum Deposition System_#2

Equipment size 3600 Ø X 4500mm

Weight About 38 tons

Main drum Width 2,200mm (two-drum)

Vacuum pump Dry pump + cryo pump (8 ea.)

Maximum vacuum 5 x 10-6 torr (work vacuum: 10-4 torr)

Roll drive speed Maximum 15M/min

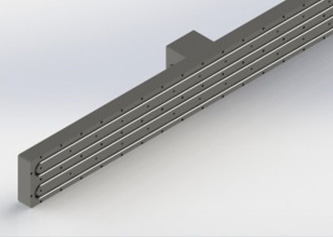

Attached cathode Width 1,600mm, 6 ea. (simultaneous deposition of six types of metal)

Roll-to-Roll Continuous Vacuum Deposition System_#3

Equipment size 2800 Ø X 3800mm

Weight About 25 tons

Main drum Width 1,800mm (two-drum)

Vacuum pump Dry pump + cryo pump (8 ea.)

Maximum vacuum 5 x 10-6 torr (work vacuum: 10-4 torr)

Roll drive speed Maximum 15M/min

Attached cathode Width 2,030mm, 6 ea. (simultaneous deposition of six types of metal)

Film Winding Machine #2

- Capable of winding/rewinding at the maximum drive speed (20M/min)

- Precise tension control by attaching a load cell (20kg)

- Prevention of film rolldown using a servo motor

- Can use a material with a broad width of 1,600mm or wider

- Attached with anti-static, cover to prevent foreign matters, and adhesive roller

- In possession of a guide roller to control creases for each film thickness

Film Winding Machine #3

- Capable of winding/rewinding at the maximum drive speed (20M/min)

- Precise tension control by attaching a load cell (20kg)

- Prevention of film rolldown using a servo motor

- Can use a material with a broad width of 1,600mm or wider

- Attached with anti-static, cover to prevent foreign matters, and adhesive roller

- In possession of a guide roller to control creases for each film thickness

Wide Width Slating Machine

For Cutting Wide Width Films

- Adjustment of film width according to work environment and demand of customers

- Maximum width of about 1,450mm for winding films

- Can perform slating for up to four split parts

- Prevention of film rolldown through tension control

- Improvement of productivity through winding and slitting of finished product packing

Narrow Width Slating Machine

For Cutting Narrow Width Films

- Can exclusively cut sheets

- Attached with an anti-slip rubber roller and can apply precise control

- Maximum width: 700mm

- Maximum length: 1,000mm

Equipment Status

Quality Control Equipment

Vacuum Leak Detector

Model name (manufacturer)MSE-2403(SHIMADZU)

Measured items

- Vacuum leak of vacuum equipment

- Helium leak detector

Automatic Surface Resistance Measurer

Model name (manufacturer)FPP-RS8-1G(BEGA)

Measured items

- Contact/non-contact sheet resistance

- Conductive film for thin-film research

Haze Meter (Turbidity)

Model name (manufacturer)NDH-5000

Measured items

- Haze

- Total light transmittance

- Diffuse transmittance

- Parallel transmittance

- Turbidity

Spectral Color Difference Meter

Model name (manufacturer)SA-4000

Measured items

- XYZ

- Lab

- ΔLab

- L*a*b

- ΔL*a*b

- ΔE

- ΔE*

Simple Color Difference Meter

Model name (manufacturer)CM2600D (Minolta)

측정항목

- Lab

- ΔLab

- L*a*b

- ΔL*a*b

- ΔE

- ΔE*

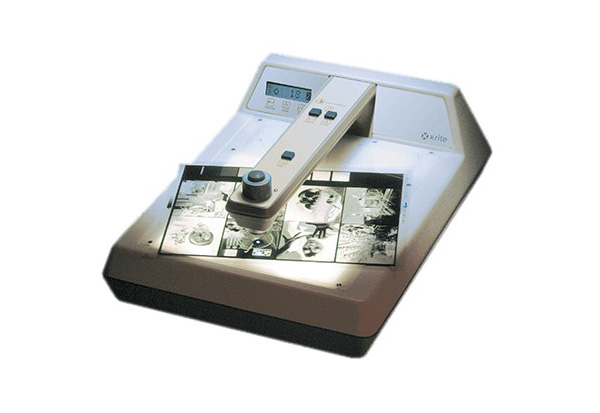

Optical Density (OD) Measurer

Model name (manufacturer)361T (X-rite)

Measured item

- Measurement of optical density of thin films

Micro Glossmeter

Model name (manufacturer)AG-4443

Measured items

- Micro-gloss60∘( 0∼1000 GU )

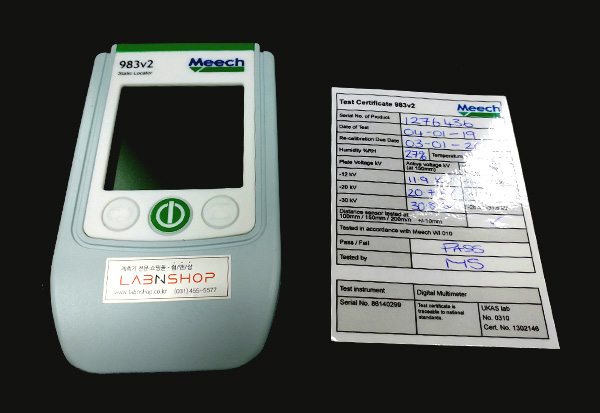

Static Meter

Model name (manufacturer)983v2

Measured items

- Equipment that measures static electricity generated by electronic parts, printed products, and films

Process Flow of Film Deposition Division

Work Process of Film Deposition Division

1. Warehousing of raw materials

Warehousing management of raw materials

2. Total warehousing inspection and sampling

Sampling of warehoused materials and data collection

3. Winding of exclusive bobbin

Winding of exclusive 6-inch FRP branch for the equipment

4. Surface pretreatment (ion beam source)

Surface reforming or pretreatment of substrates

5. Optimization of sputtering deposition process

Degree of vacuum, gas injection, roll speed, power supply, etc.

6. Quality inspection on finished products (Production Management Team)

Total external inspection of finished deposition products and storage of samples

7. Final quality inspection and release (Quality Control Team)

Data measurement for each lot (color difference, OD, gloss, transmittance)

8. Packing and standby for shipment

Completion of packing and standby for shipment (film warehouse)